InSkin™ – Zero Gap Decorative Integration is a negative vacuum forming skin manufacturing process that allows a decorative or function feature to be inserted into the thermoplastic olefin skin resulting in “zero gap” and flushed finish.

Benefits

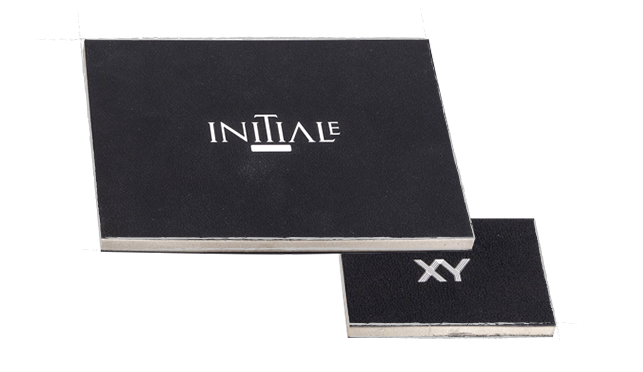

- Enables extensive range of materials to be inserted in the skin without gaps

- Offers exceptional fit and finish

- Enables flexibility to insert shapes and features to create unique styling and branding opportunities

Don’t hesitate to contact our teams for further information.